Fitness for Service (FFS) and Engineering Critical Assessment (ECA) Software Automates the Fracture Mechanics Methods of BS 7910 and API 579

Complex, Real-life Applied Fracture Mechanics Methods done Quickly and easily

Material ECA was designed from the ground up to address the issues common to all FFS experts and ECA practitioners:

Straightforward Real-World, Full-Lifetime Assessments

Encapsulating functionality as interoperable components enables designing and conducting assessments as a series representing a timeline, in parallel representing sensitivity cases, or nested both ways, as desired.

Workflow Visibility

The collaboration features allow users to share access to their Material ECA projects with others enabling teamwork, real-time feedback, and transparent verification.

Interoperability With Other Software and Platforms

Material ECA can efficiently import and export data in several common formats, including Excel and JSON.

Access to Professional Quality ECA Software

Material ECA is available online.

Demonstrations, Tutorials, and Case Studies

Functionality Encapsulated as Components

Encapsulating functionality as components is the heart of Material ECA. Components, such as unstable fracture, ductile tearing, and fatigue crack growth, can be assembled with custom chain and group components to represent real-world scenarios.

The fracture mechanics components automate the methods described in

BS 7910. However, additional components can be added to automate the methods described in other standards, such as API 579 / ASME FFS, or new methods, such as environmental cracking.

Chain Component

Components can be added to a Chain component in series, like links in a chain, such that the initial flaw for one component is the final flaw from the previous component.

If any component added to a Chain is unacceptable, the Chain will be unacceptable. The final flaw from a Chain is the final flaw from the final added component.

Group Component

Components can be added to a Group component to be processed in parallel. The initial flaw for each added component is the same. Like the Chain, if any component added to a Group is unacceptable, the Group will be unacceptable.

The final flaw from a Group is the largest flaw from any of the added components.

Chain and Group components can be nested, providing unprecedented flexibility to easily assess complex, real-world issues.

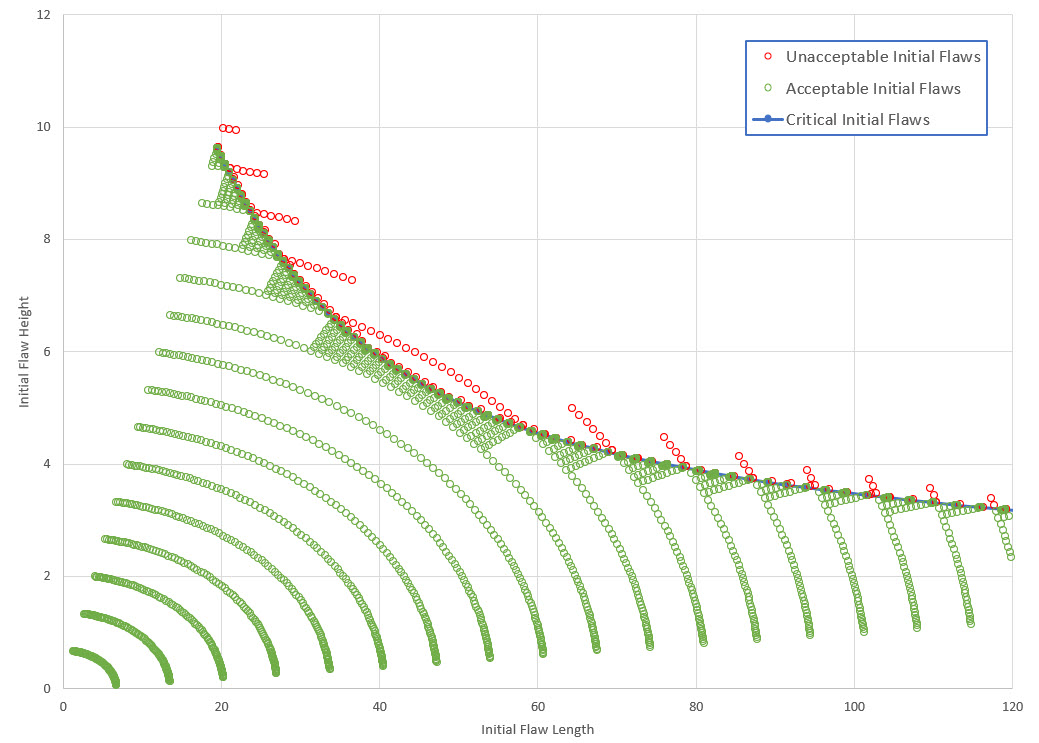

Critical Initial Flaw Solver

The Solver can be run on any component to identify the smallest unacceptable flaws reliably and quickly. Sensitivity cases can be quickly run to investigate and safely handle “non-unique solutions” inherent to BS 7910 methods.

Max Flaw Size

The Max Flaw Size component is lightweight and can add customized flaw size limits to Fatigue, Chain, and Group components. Solver results for critical initial flaws are commonly used in the design of Max Flaw Size components.

Import and Export Data and Results

Material ECA results can be exported directly as Microsoft Excel Workbooks, and automatically generated reports can be exported as PDF files. Furthermore, Material ECA data and results formatted as JSON can be imported or exported. This means we can programmatically get and process data from various sources, such as spreadsheets, databases, or miscellaneous data files, rapidly into Material ECA. This saves time, improves quality, and makes results far more useful.

Exporting data as JSON makes it easy to feed your data-driven digital solutions, such as accurate and prioritized inspection plans, detailed insights on asset health monitoring, and life extension judgments.

JSON is a common, lightweight data-interchange format that is easy for humans to read and write and easy for software or any digital system to parse and generate. JSON uses human-readable text to store and transmit data objects consisting of attribute-value pairs and arrays (or other serializable values) [see json.org].

Collaborative Platform Enables Teamwork

Sharing Material ECA projects online with experts, specialists, managers, clients, and independent reviewers improves workflow visibility and communication and reduces delays in constructive feedback.